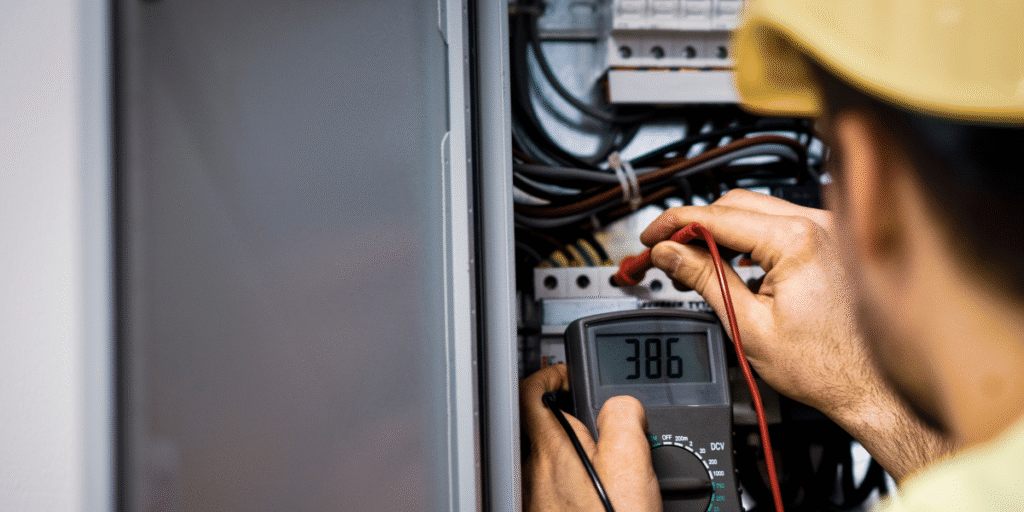

Arc flash studies protect your people and equipment—and keep you compliant with NFPA 70E and OSHA expectations. Direct Source Industrial Solutions delivers turnkey studies: field data collection, single‑line updates, short‑circuit & coordination, IEEE 1584 incident‑energy calculations, and printed/installed labels. We also provide mitigation recommendations and training.

What’s included:

Trusted by industrial facilities across SoCal

We deliver a complete, code‑aligned package designed for compliance, safety, and uptime:

Equipment nameplate data, protective devices, conductor sizes/lengths, and system topology.

Create or reconcile your single‑line so modeling and labels are accurate and auditable.

Verify available fault currents; coordinate protective devices to minimize nuisance trips.

Incident energy, arc‑flash boundary, and PPE category for each labeled location.

Durable, compliant labels installed on the correct gear with location‑matched IDs.

Recommendations (settings, ARMS/ZSI, current‑limiting) and worker training upon request.

Typical updates recommended every 5 years or after significant electrical changes.

Oil & gas, utilities, water/wastewater, manufacturing, distribution, food & beverage, aerospace, commercial campuses.

Scope varies by facility size, available documentation, and number of labeled locations.

Small sites typically start in the low five figures; multi‑building campuses are higher.

We’ll quote after a quick discovery call or site walk.

Yes—latest methodology and labeling/PPE guidance are applied.

We create or reconcile single‑line diagrams as part of the engagement.

Yes—durable labels printed and installed on the correct equipment.

After significant electrical changes or generally every 5 years.

Yes—qualified/unqualified worker training is available on request.

12329 Telegraph Road, Santa Fe Springs, CA

24/7 Support • Service Area: Los Angeles, Orange County, Long Beach, Anaheim, Burbank, Ventura

CA Contractors – Electrical & Mechanical